Categories

New products

-

Standard Spiral Wound Gasket

The professional manufacturer of Standard Spiral Wound Gasket in China,offers fine Standard Spiral Wound Gasket for you.

-

Nuclear Spiral Wound Gasket

The professional manufacturer of Nuclear Spiral Wound Gasket in China,offers fine Nuclear Spiral Wound Gasket for you.

-

Non-rounded Spiral wound Gaskets

The professional manufacturer of Non-rounded Spiral wound Gaskets in China,offers fine Non-rounded Spiral wound Gaskets for you.

-

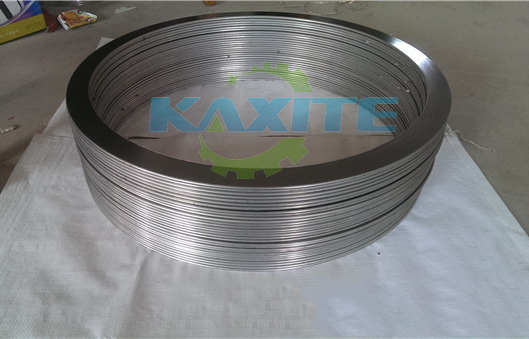

Lens Ring Joint Gasket

The professional manufacturer of Lens Ring Joint Gasket in China,offers fine Lens Ring Joint Gasket for you.

-

Double Jacket Gasket

The professional manufacturer of Double Jacket Gasket in China,offers fine Double Jacket Gasket for you.

Ceramic Fiber Board

Kaxite provide all kinds of ceramic fiber board, adopting corresponding blowing fiber (ST, HP, HAA, HZ) as the material, are produced by vacuum formed technology. Do not only possess the same, function of fiber, but also have hard texture, excellent toughness and intensity, and excellent fiber resistant and heat preservation.

|

Prime Features:

Prime Features: Specification:

Application |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||